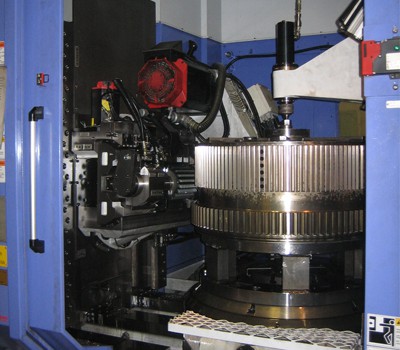

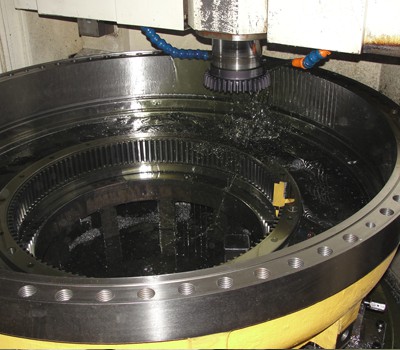

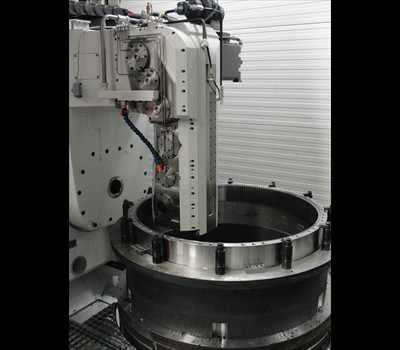

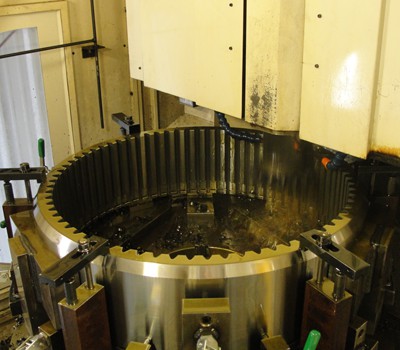

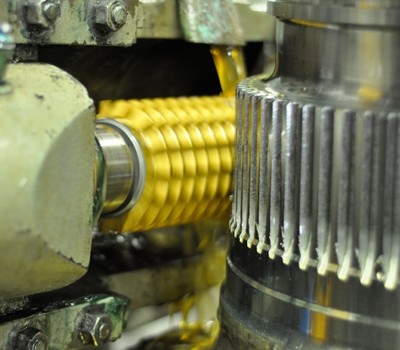

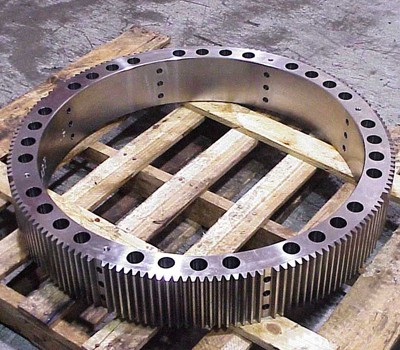

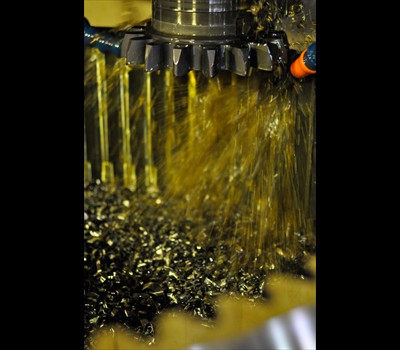

Richardson Manufacturing Company is pleased to offer precision gear cutting capabilities for a variety of industries which include but are not limited to industrial equipment, mining, oil & gas, and heavy construction. These capabilities include state of the art CNC hobbing, shaping, and gashing machine equipment. The hobbing machines can accommodate parts with a diameter of up to 78.7” (2000 mm) or a max axial face width of up to 46” (1168mm), with gear teeth as large as 1.6 D.P. (15.88 module). RMC also has heavy-duty manual and CNC shapers that can accommodate parts that are up to 69” in diameter, 60” tall, and cut gear teeth as large as 1 D.P. (25.4 module) with up to 17” of stroke length. Lastly, the 2400 size gear Gasher machine gives RMC the capability to perform either external hobbing or gashing (rough or finish applications) of spur and helical gears up to 78.7” in diameter with an axial stroke length of about 69” (1760mm). This machine is also configured with an internal gashing head that can cut internal teeth of parts up to 94.5” (2400mm) in diameter. We can work with a wide range of materials depending on customer needs, from prototype to production. Our state-of-the-art gear inspection equipment can perform full analytical gear inspection to verify the quality of the parts produced to ensure meeting the specifications required by the customer.

hobbing or gashing (rough or finish) of spur, helical, or double helical gears up to

78.7” (2000mm) in diameter with an axial stroke length of about 69” (1760mm).

In addition, this machine is also configured with an internal gashing head that

can cut a part up to 94.5” (2400mm) in diameter. We can work with a wide range

of materials depending on customer needs, from prototype to production. Our

state-of-the-art gear inspection equipment, newly equipped with the AGMA2015

standard, or other standards as required, can perform full analytical gear

inspection to verify the quality of the parts produced to ensure meeting

the specifications required by the customer.

hobbing or gashing (rough or finish) of spur, helical, or double helical gears up to

78.7” (2000mm) in diameter with an axial stroke length of about 69” (1760mm).

In addition, this machine is also configured with an internal gashing head that

can cut a part up to 94.5” (2400mm) in diameter. We can work with a wide range

of materials depending on customer needs, from prototype to production. Our

state-of-the-art gear inspection equipment, newly equipped with the AGMA2015

standard, or other standards as required, can perform full analytical gear

inspection to verify the quality of the parts produced to ensure meeting

the specifications required by the customer.

| Gear cutting processes | Hobbing, Shaping, Spline Milling, Gashing | ||

| Gear Types | • Internal Spur Gear • Pre-grind Roughing • External Spur Gears • Helical gears • Internal and External Gear Gashing |

||

| Shaping Workpiece Diameter | Max 69” |

||

| Shaping tooth size | Max 1 D.P. / 25.4 Mod |

||

| Shaping Stroke Length | Max 17” |

||

| Shaping Workpiece Height | Max 60" |

||

| Hobbing Max Workpiece Diameter | Max 78.7” / 2000 mm |

||

| Hobbing Tooth Size | Max < 1 D.P. / > 25.4 Mod |

||

| Gashing Max Workpiece Diameter | Max Internal 94.5” / 2400mm |

Max External 78.7” /2000 mm |

|

| Gashing Max Workpiece Height | Max Internal 57.7” / 1460mm |

Max External 129.9” /3300 mm |

|

| Gashing Tooth Size | < 1 D.P. / > 25.4 Mod | ||

| Material pre-processing | All gear blanks and material can be turned/milled in-house before gear cutting. | ||

| Workholding | Custom fixturing and chucks designed and built in-house as needed. | ||

| Applications |

|

||

© 2014 Richardson Manufacturing Co. All rights reserved. Privacy Policy | Sitemap | Careers Site created by Resolute Design